la poudre d cuivre machine de separateur

-

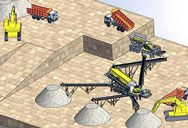

de concasseur usine 1000 tph jilin

-

convoyeur a bande conception simple en afrique du sud

-

fabricant de machine de broyeur

-

de concassage Afrique concasseur de marbre

-

machine a granule de bois a vendre

-

concasseur à cone advance

(PDF) Roll crushers and mills (Design review)

2022.3.29 The classification of roll crushers and mills for the disintegration of lumpy and loose materials processed at the enterprises of chemical, mining, construction, food and electrode industries, as...

Bavarder sur Internet

Classification of roll crushers Request PDF - ResearchGate

2007.4.1 A classified system based on the basic elements, their profile and material draw-in conditions can prove useful as a basis for the assured selection of roll crusher types in

Bavarder sur Internet

Crushers: 5 types and their main failures

2024.4.19 Some of the most well-known models are the High Pressure Grinding Rolls (HPGR) and the Low Speed Sizer. The HPGR uses two rotating rolls that turn in opposite directions. The crusher’s hydraulic cylinder system

Bavarder sur Internet

Classification of Roll Grinders for Lumpy and Bulk Materials

2021.3.20 A classification of roll crushers and mills for lumpy and bulk materials used in equipment at enterprises in the chemical and food industry as well as at factories involved in

Bavarder sur Internet

Types of Crushers: Choosing the Right One for

2024.7.17 Roll Crusher. Roll crushers crush materials through the compression action of two rotating rollers. They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive

Bavarder sur Internet

What Are the Differences Between The 7 Types

2024.7.15 Roll crusher is usually used in small scale production and applied to crush abrasive ores or rocks. It can produce fine-sized product like manufactured sand and without dust spreading. Hammer crusher is composed

Bavarder sur Internet

Crushers and Screens - Springer

2017.8.26 Roll crushers (figure 10.2) are used essentially for the size-reduction of friable to medium-hard materials when products are required containing a minimum amount of

Bavarder sur Internet

Double Roller Crushers - SolidsWiki

2022.7.7 Double Roller Crushers are Roller Crushers that are widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, and

Bavarder sur Internet

Roll Crusher - an overview ScienceDirect Topics

6.1 Introduction. Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions. Single roll crushers are also available which rotate a single

Bavarder sur Internet

Single Roller Crushers - SolidsWiki

2022.7.7 Single Roller Crushers are designed to last and are suited for primary, heavy-impact applications. They can take on rugged feed such as refuse and 100% rock, but may

Bavarder sur Internet

Roll crushers – ERC and double roll crusher – FLS

FLS Double Roll Crusher DRC 22-28: Primary crushing: Bauxite, ore, coal, overburden: 0 to 500 mm: 6,000 to 8,000 tph: Eccentric Roll Crusher ERC® 18-14: Primary crushing: Hard rock and ore-550 – 1,850 metric tph: Eccentric Roll Crusher ERC® 22-20: Primary crushing: Hard rock and ore-1,050 – 3,450 metric tph: Eccentric Roll Crusher ERC ...

Bavarder sur Internet

HRC Roll Crusher Hazemag North America

Housing and drive bracket of the HAZEMAG Roll Crusher are very sturdy and thus suitable for heavy-duty applications. They are fitted with easy to exchange wear parts. The design of the housing allows a crushing segment changing

Bavarder sur Internet

Design, Fabrication and Testing of a Double Roll Crusher

2024.7.25 Figure 1: Double roll crusher geometry 2.1.5 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5]. For rolls that have equal radii and length, tangents drawn at the point of contact of the particle

Bavarder sur Internet

Double-Roll-Crusher - thyssenkrupp Polysius

Due to the low crushing ration, the thyssenkrupp Polysius Double-Roll-Crusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the lime-industrie. Contact. thyssenkrupp Polysius GmbH. General Contact. Graf-Galen-Straße 17. 59269 Beckum

Bavarder sur Internet

Design, Fabrication and Testing of a Double Roll Crusher

2016.5.25 A developing nation like Nigeria, with huge deposit of different solid minerals and rocks, needs to explore the processing of these solid minerals to reduce dependence on petroleum. The old ways of stone crushing by hand is still being practiced in several villages and towns in Nigeria. Design and production of an indigenous roll crusher from locally available

Bavarder sur Internet

Experiment 03 Reduction Ratio of Roll Crusher PDF

2024.3.16 The document describes an experiment to test a laboratory roll crusher. The objectives are to study the parts of the roll crusher, perform a crushing test on a sample, analyze the crushed product using sieve analysis, and calculate the reduction ratio. The apparatus used includes the roll crusher, rock sample, sieve set, sieve shaker, and balance. Roll crushers are

Bavarder sur Internet

Single Roller Crusher Simple And Efficient Crushing

2023.3.11 By using a single roller crusher, the cement plant can save space and energy while achieving the desired product quality. Future Developments of single roller crusher. Research and development efforts are underway to improve the performance and efficiency of single roller crushers. New materials and surface treatments for rollers are being ...

Bavarder sur Internet

difference between smooth roll crusher and jaw crusher

A smooth roll crusher consists of a rotating cylindrical shell with a pair of smooth crushing rolls that rotate towards each other. The material is fed into the top of the crusher and crushed by the compression forces between the rolls. This type of crusher produces a more uniform product size distribution with minimal fines.

Bavarder sur Internet

Compact, robust and high-performance: New ERC25-25 eccentric roll ...

Semantic Scholar extracted view of "Compact, robust and high-performance: New ERC25-25 eccentric roll crusher revolutionizes primary crushing in under- ground mines. Kompakt, robust und leistungsstark: Neuer Exzenterwalzenbrecher ERC25-25 revolutioniert die Primärzerkleinerung unter Tage" by Piotr Szczelina et al.

Bavarder sur Internet

Penjelasan Lengkap Gyratory Crusher yang

2022.12.2 Tooth Roll Crusher dapat bekerja lebih baik dibandingkan dengan Smooth Roll Crusher, tetapi Tooth Roll Crusher terbatas karena tidak dapat memecah padatan yang kasar. Alat ini bekerja berdasar pada prinsip

Bavarder sur Internet

Mid-range rolls crushers – tough on any material - FLSmidth

The Essa Rolls Crusher range includes: Essa RC2000 Rolls Crusher – compact and rapid standalone rolls crusher with 2 x 200 mm rolls. Common applications include coal and diamond mining. Essa RC3000 Rolls Crusher – a larger and much more powerful rolls crusher with 2 x 350 mm rolls. A choice of two configurations gives you flexibility for ...

Bavarder sur Internet

Inilah Cara Kerja Roller Crusher untuk Menghasilkan Material ...

Cara Kerja Roller Crusher Mesin roller crusher terdiri dari rangka mesin, dua rol yang berputar dipasang secara paralel di dalam rangka, serta beberapa mesin yang dilengkapi dengan sistem penggerak tambahan, seperti sabuk konveyor, untuk memasukkan material ke

Bavarder sur Internet

Roll Crusher - Zoneding Machine

2024.11.11 Roll Crusher Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. Processing capacity: 5-100 t/h Roller diameter: 400-700 mm Feeding size: ≤25-≤100 mm ...

Bavarder sur Internet

Mining Technologies Eccentric roll crushers ERC

2020.8.21 roll with constant stroke in the entire crusher cavity allows for higher reduction ratio and more effective use of crushing energy. Under load, the freely rotatable roll slowly turns backwards which distributes the loads over the entire roll circumference and ensures uniform wear and maximized lifetime of the roll liners.

Bavarder sur Internet

Innovative roll crusher technology - Size Technology GmbH

Thanks to our innovative roll crusher technology, we develop high throughput crushers for various areas of applications.

Bavarder sur Internet

Types of Crushers Explained: Everything You Need to Know

2024.4.19 A short-head cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm. A fine cone crusher, also known as a tertiary cone crusher, is used for the production of They are manufactured to produce very fine output sizes, mostly below 6 mm.

Bavarder sur Internet

Comparison of breakage behavior between the sieving crusher

2018.9.28 ABSTRACT Comparison of breakage behavior of coals is conducted between the industrial sieving crusher (SC) and ordinary teeth roll crushers in different breakage flow sheets. Two types of coals, about 10 tons, are used for each comparison, and consumed energy and size distribution of products are analyzed. Due to differences in roll rotation rate and teeth

Bavarder sur Internet

Design, Fabrication and Testing of a Double Roll Crusher

2016.5.25 Figure 1: Double roll crusher geometry - "Design, Fabrication and Testing of a Double Roll Crusher" Skip to search form Skip to main content Skip to account menu. Semantic Scholar's Logo. 221,748,439 papers from all fields of

Bavarder sur Internet

Articles liés

- concasseur mobile étiqueté

- fabricant de canne à sucre de concasseur

- équipement de concasseur et de séparateur pour l or

- matériel de construction et autres articles connexes

- échelle de concasseur de calcaire

- application principe de fonctionnement de lécran vibratoire

- entretien dusine de ciment

- Équipements de tamisage du sable utilisé

- concasseurs de pierre en belgique

- les usines de fabrication de soie en chine

- concasseur à machoires cot de concasseur broyeur de pierres

- broyeur semi mobiles

- concasseur mobile charbon de cne pour la location en

- usine concasseur profil echantillon

- ceinture minière transporteur

- broyeur à boulets mumbai

- ventes de broyeur a bentonite

- diametro 900 cono chancadoras de peso

- machine Afrique concasseur de minerai de fer malaisie

- terne terne au laminoir

- dur electrod face pour concasseur à marteaux

- broyage ccuivreée du fait à la machine

- marbre ecrasement de broyage Belgique

- américain fait la machine de fraisage paillasse

- meulage fabricants de moulins au Algérie concasseurs

- pierre machine de concassage l'équipement

- production de cobalt de cuivre

- Afrique concasseur de roche dans le sud de la Californie

- liste de l'industrie de concassage au Népal

- pour concasseur giratoire en allemagne