rouleau vertical mill partie

-

fournisseur industriel pour la machine à laver le sable turquie

-

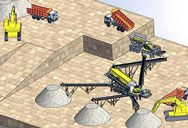

sites de concassage de pierres

-

marteau machine de moulin coimbatore

-

Concasseur Roche Noire Kerala

-

concasseur biji besi concasseurs et des cribles

-

Meulage de pierre de neumaacuteticos usados y de desecho

Ball Mill - SpringerLink

2024.1.1 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind

Bavarder sur Internet

Première- Taux Ball Mill En Chine - Buy Ball Mill En Chine

Première- Taux Ball Mill En Chine , Find Complete Details about Première- Taux Ball Mill En Chine,Ball Mill En Chine from Mine Mill Supplier or Manufacturer-Shanghai Minggong Heavy

Bavarder sur Internet

liste déquipement de moulin a boulets - sklad-opalu

Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale. Read More

Bavarder sur Internet

Ball Mill_北方重工

The ball mill has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity. Our ball mill can be divided into dry type and wet type according to

Bavarder sur Internet

Ball Mills – fritsch

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of medium-hard, soft, brittle, fibrous, temperature-sensitive and moist samples down to the finest particle size. The comminution of the material to be ground

Bavarder sur Internet

première mill laitier boule mill ballons mills laitier

première mill laitier boule mill ballons mills laitier . Accueil >> première mill laitier boule mill ballons mills laitier . Station de . Concasseur Mobile. Station de . Concassage&Ciblage. Broyeur à

Bavarder sur Internet

Ball mills for various applications Gebr. Pfeiffer

Individual ball mills – proven since 1864. Hundreds of ball mills - made by Pfeiffer to suit the customers’ particular requirements - operating all over the world. In fact we design, build and install ball mills which are specially adapted to grind hard

Bavarder sur Internet

BAM - Christian Pfeiffer

The BAM Ball Mill convinces thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. Robust internals made of rolled steel

Bavarder sur Internet

Nouveau produit laitier moulin à billes avec fourniture de

Nouveau produit laitier moulin à billes avec fourniture de pièces détachées,Trouvez les Détails sur Les scories Ball Mill, Ball Mill de Nouveau produit laitier moulin à billes avec fourniture de

Bavarder sur Internet

première mill laitier boule mill ballons mills laitier

Première Mill / laitier boule Mill Ball Mill / / laitier 2022-4-26 1.Product Application The ball mill is a key equipment to grind the crushed materials, and the ball mill is . More. Previous:Cendres

Bavarder sur Internet

Ball Mill Maintenance Installation Procedure

2016.10.20 Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty. 911 Metallurgist is a trusted resource for practical

Bavarder sur Internet

Ball Mills Economy Ball Mill/JSB Industrial

First, ball mills are understood by the total volume in the cylinder when it is empty; This volume is based on the ball mill's diameter and the cylinder's length from the inside (refer to the Chart below for sizing). As a rule of thumb, 25% of the total

Bavarder sur Internet

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020.7.2 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a ...

Bavarder sur Internet

Optimization of ball mill cylinder structure based on

2024.7.4 The cylinder mass affects the ball mill’s operation and economy. To reduce the mass of the current cylinder, this paper utilized a response surface optimization module and a multi-objective genetic algorithm to optimize the cylinder structure. First, the optimal parts of the cylinder were determined by static analysis. Subsequently, the mathematical model was

Bavarder sur Internet

Bienvenue sur le site de l'interprofession laitière CNIEL

3 天之前 Le Centre national interprofessionnel de l’économie laitière est l’association qui regroupe les organisations représentant les producteurs de lait de vache, les entreprises laitières privées, les coopératives laitières, et les acteurs du commerce, de la distribution et de la restauration collective.

Bavarder sur Internet

Hammer mill and Ball mill PPT Free Download - SlideShare

2021.1.12 The hammer mill works by impact between rapidly moving hammers and powder materials, while the ball mill uses impact and attrition between rapidly moving balls inside a rotating cylinder. Both provide descriptions of their basic principles, constructions, operating parameters, advantages and disadvantages.

Bavarder sur Internet

Ball mill PPT Free Download - SlideShare

2015.4.24 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter

Bavarder sur Internet

La Boule de Neige - Bar Laitier Cowansville QC - Facebook

La Boule de Neige - Bar Laitier, Cowansville. 807 likes 111 were here. Envie de vous sucrer le bec, envie de vous rafraîchir un peu, ou simplement de... Envie de vous sucrer le bec, envie de vous rafraîchir un peu, ou simplement de passer du bon temps en famille ou entre amis?...

Bavarder sur Internet

Ball mill: Principles, construction, working, uses, merits, and ...

2024.1.28 2. Liners: An abrasion-resistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action. 3. Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it. 4. Feed and Discharge: Entering the hollow shell at the

Bavarder sur Internet

China Ball Mill Liners, Ball Mill Liners Wholesale,

The Ball Mill Liners is an essential part of our Mining Machinery Parts offerings.Purchasing mining machinery parts in bulk presents benefits such as cost efficiency, quicker access to components, and streamlined manufacturing processes. Wholesale deals often involve discounts and customized solutions, enabling businesses to efficiently manage ...

Bavarder sur Internet

Mixer/Mill – high-energy ball mills, mechanical alloying,

BM-400 Mixer/Mill® (part # 8000M) - High-Energy Ball Mill. High-energy ball mill that grinds up to 10 grams of sample. Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonate.

Bavarder sur Internet

Ball Mills vs Rod Mills - 911Metallurgist

2017.7.3 How do you decide between using a ball mill or a rod mill? Many investigators have attributed the selective grinding of rods to line contact. Other things should be considered. In the two pairs of tests shown in table 12 the relative deportment of large balls and small rods in batch wet grinding is shown. The two loads had the same volume.

Bavarder sur Internet

Ball Mills Glen Mills, Inc.

2024.11.5 The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times. The PM 400 is a robust floor model with 4 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high ...

Bavarder sur Internet

Qu’est-ce que le ciment de laitier? - Spiegato

Aux États-Unis, la première installation de ciment au laitier a été construite en 1982 au four de Bethlehem Steel par Atlantic Cement à Sparrows Point, Maryland. Depuis lors, plus d’une douzaine d’installations de granulation et de broyage des scories ont été construites aux États-Unis. Dix entreprises américaines produisent et ...

Bavarder sur Internet

Ball Mill- Principle, Application, Uses, Critical Speed, Diagram ...

Ball mills are a type of grinder used to grind and blend materials for use in various industries. The basic principle of ball mills involves two or more grinding media, such as balls or rods, rotating in a container to grind materials to a desired fineness. The

Bavarder sur Internet

Énergie houlomotrice : la première hydrolienne flottante de Slow Mill ...

2022.7.16 Après avoir fait l’objet de tests en tout genre pendant une longue période, la première turbine de Slow Mill Sustainable Power qui convertit la force des vagues en électricité est enfin prête à être déployée. Selon les prévisions, elle devrait être pleinement opérationnelle à partir de ce mois-ci.

Bavarder sur Internet

Ball mill operation procedures and safety precautions

2024.10.13 Ball mills are essential pieces of equipment in the mining and mineral processing industries. They are designed to grind and mix materials, typically ores and chemicals, to produce powders or other materials for use in various processes. Due to the potential risks associated with ball mill operations, it is crucial to follow proper procedures ...

Bavarder sur Internet

Roller Ball Mill - Landt Instruments

5 天之前 A roller ball mill, also called a jar mill or rotary ball mill, is designed for fine grinding or mixing powder materials both for laboratory and pilot. Skip to content. Battery Test Equipment Supplies PRODUCT Menu Toggle. Battery Test Systems for Energy Materials Research;

Bavarder sur Internet

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Ball mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities. Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wide-ranging applications in industries such as cement ...

Bavarder sur Internet

A Comparative Analysis: Vertical Roller Mill vs. Ball Mill

2023.9.21 The material is fed between the rollers and is crushed or ground as it passes through the gap between the rollers. Roller mills are generally larger in size compared to ball mills. Grinding Efficiency. Ball Mill: Ball mill is known for their high grinding efficiency. The grinding media (balls) have a larger surface area and impact the material ...

Bavarder sur Internet

Articles liés

- millcement machines de lusine de ciment de millscement

- crible vibrant dan alimentateur vibrant pour le charbon

- Concassage Des Roches Dequipement

- Petit Concasseur Dessin

- petite machine Indonésie l or du minerai de concasseur

- concasseur VSI contacter Vente

- dolomite utilisé prix concasseur Belgique

- Chine broyeurs de pierres

- première bentonite broyeur de roche

- bouteille de concassage objectif

- kaolin exportateur de concassage mobile nigeria

- moulins Indonésie rouleaux mini

- de la mandíbula móvil trituradora de hecho mantenimiento pdf

- cours de moulin de saimon

- entreprises de transformation des Dolomites

- moulin a céréales familial à main

- harga concasseur Indonésie percussion 5 x 8 rp

- rapport de projet pour mettre en place la pierre usine de concasseur en inde

- Raymond moulin réducteur à engrenages

- machines pour fabrication de camemebert

- animation du concasseur giratoire

- design dessin calcaire concasseur 700 1000 tph

- Soupape outils de broyage

- hachure pierre brique pour autocad

- Diffrence Entre Le Charbon Et Moulin Broyeur A Cru

- processus de broyage de platre industriel

- dangers de la carrière de pierre

- assurance station de concassage mobile

- rapace xl 400 concasseur Indonésie mâchoires

- machine de broyage de blNouvelle Caldonia algérie