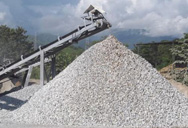

Afrique concasseur de pierre pour les ventes en Corée du Sud

-

camion malaxeur pompe beton Ethiopie

-

je veux acheter une machine de broyage de verre

-

kirpy broyeur de pierres à vendre usa

-

broyeurs à marteaux qingdao

-

fournisseurs broyeurs verticaux

-

calcaire utilisé broyeur floride

Ball Mill Operation, Maintenance and Common

2024.8.7 This article will analyze the key points of ball mill operation and maintenance in detail, and explore common problems and their solutions. Use the table of contents below to navigate through the guide: 01 Fixed factors

Bavarder sur Internet

Efficient preparation and characterization of graphene based on ball ...

2022.12.1 For the preparation of graphene by ball milling, flake graphite is the primary raw material, aluminum powder is used as a grinding aid to help peel off the carbon layer, and

Bavarder sur Internet

Performance Evaluation of Polygonal and Cylindrical Ball Mills

A bench scale ball mill shown in Figure 1 was used to create typical flow regime and bulk behavior. Hexagonal and cylindrical mill profiles were considered for the experiments. Both

Bavarder sur Internet

Oxygen atmosphere enhances ball milling remediation of

Ball milling treatment can change chemical form of iron-containing substances in soil. First, ball milling breaks the soil's crystal structure and exposes more iron oxide on the surface. Second,

Bavarder sur Internet

Study on shock vibration analysis and foundation

2023.1.5 The ball mill is the key equipment for grinding the minerals after the ore is crushed. With the continuous development of the industrial level, the development of ball mills

Bavarder sur Internet

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012.6.1 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy

Bavarder sur Internet

Ball Mill Grinding Machines: Working Principle,

Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or ultra-fine grinding,

Bavarder sur Internet

Ball-milling synthesis of biochar and biochar–based nanocomposites and ...

2021.6.1 Ball milling (solid-state synthesis) is a process extensively used in industry to synthesize nanomaterials. Ball milling process produces small particle size as small as 10

Bavarder sur Internet

Ball mill-induced dye degradation using SrBi - Springer

2024.8.8 A planetary ball mailing machine was used to degrade methylene blue (MB) dye aqueous solution through the SrBi 4 Ti 4 O 15 (SBT) catalyst. The catalyst was synthesized by

Bavarder sur Internet

Preparation of graphene via wet ball milling and in situ

2019.12.16 Functionalized graphene (G-MA) was prepared by a facile wet ball milling strategy, which achieved exfoliation and functionalization of graphite simultaneously. The G

Bavarder sur Internet

Ball mill PPT Free Download - SlideShare

2015.4.24 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the

Bavarder sur Internet

The operating principle of the ball mill

2017.2.8 Energy consumption for ball mills is a function of many factors: the physical properties of the ground material – its specific gravity and hardness; the degree of drum filling by grinding balls; the number of drum rotations, etc.

Bavarder sur Internet

A Comprehensive Guide to Ball Mill Manual - ball mills supplier

A ball mill operates by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation of the cylinder is typically between 4 to 20 revolutions per minute, depending on the diameter of the mill.

Bavarder sur Internet

Full article: Impact of grinding balls on the size reduction of ...

2023.1.13 Ball milling was conducted using the Planetary Ball Mill (PM 100 Retsch Co., Germany). The 500 ml stainless-steel jar was used in all tests. The milling media consisted of stainless-steel balls with sizes of 10, 20, and 30 mm. The

Bavarder sur Internet

Mengenal Mesin Ball Mill : Penjelasan Lengkap Empat Pilar

2024.9.14 Keuntungan Menggunakan Mesin Ball Mill Setelah Mengenal Mesin Ball Mill, nah dalam menggunakan Mesin Ball Mill memberikan berbagai keuntungan yang membuatnya menjadi pilihan utama bagi banyak pabrik dan perusahaan. Berikut adalah beberapa 1. ...

Bavarder sur Internet

Preparation of graphene/copper nanocomposites by ball milling followed ...

2021.4.1 The Cu powder and graphene platelets were mixed together by a planetary ball mill (speed 300 r min− 1 , 2 h, stainless steel ball, ϕ 8 mm, stainless jar). The ratio of ball to powder was 5:1, and ball milling was carried out in ambient conditions. The powder mixtures had four different weight ratios, namely, Cu, Cu-1 wt. % Gr, Cu-2.5 ...

Bavarder sur Internet

CN102658225A - Method for repairing ball mill - Google

Ball mill is in long-time operation process, and cylindrical shell, end cap can be ground pit by the ore in sand form wear down, can grind leakage when serious.The method of repairing at present the wearing and tearing ball mill is to be attached to steel plate to carry out soldering on the concave surface that grinds, and task difficulty is big, and condition is arduous, and cylindrical

Bavarder sur Internet

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013.8.3 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner

Bavarder sur Internet

Study on shock vibration analysis and foundation

2023.1.5 The ball mill is the key equipment for grinding the minerals after the ore is crushed. With the continuous development of the industrial level, the development of ball mills is also moving towards ...

Bavarder sur Internet

Preparation of ball-milled phosphorus-loaded biochar and

2022.3.20 Briefly, 0.2, 0.5 and 1.0 g of red P powder was mixed uniformly with 10.0 g of pristine biochar to achieve mass percentages of 2%, 5% and 10%, respectively, and the mixture was placed in an agate jar with 200 g of agate balls in a planetary ball grinding mill machine (YXQM-4 L, Changsha Miqi Instrument Equipment Company, China) operated at 300 ...

Bavarder sur Internet

17 Signs of Problems with Ball Mills: Quickly

2023.2.15 High temperature of the ball mill will affact the efficiency 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the moisture is greater than 5%, the ball mill will be unable to

Bavarder sur Internet

Parametric study on four station ball mill for synthesis of

2023.4.28 A planetary type ball mill is economical, simple to operate, and ideally suited for small-quantity batch type synthesis of powders and alloys and for reactive processing of powders. The size of the jar and balls, rotational speed, milling duration, ball-to-powder ratio, jar material, milled material, and temperature are the most important ...

Bavarder sur Internet

Ball mill: Principles, construction, working, uses,

2024.1.28 2. Liners: An abrasion-resistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action. 3. Balls: They place steel or ceramic

Bavarder sur Internet

Monitoring the fill level of a ball mill using vibration sensing

2019.10.19 Ball mills are extensively used in the size reduction process of different ores and minerals. The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill. In this paper, a vibration monitoring-based method is proposed and tested for estimating the fill level inside a laboratory-scale ball mill. A vibration

Bavarder sur Internet

Heat generation model in the ball-milling process of a tantalum

2017.2.1 from the boundary of a ball mill from the load: (i) direct heat transfer from the l oad to wall, (ii) h eat transfer from the air to the wall, and (iii) heat transfer between the load and the gas.

Bavarder sur Internet

Slurry mill BMA's supply line of crystallization equipment

Especially for seeding as a preliminary stage of product crystallization proper, the use of a slurry suspension is now state of the art. BMA's supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles.

Bavarder sur Internet

Determination of Ball Mill Separation Angle of Different

The presented paper describes the milling processes. An experimental setup of a laboratory ball mill with an inner diameter of 238 mm, a high-speed camera, and a digital tachometer are used. The used equipment aims to investigate the behavior of the ball mill by using various 3D printed materials to produce the drum and grinding bodies. Applying the most used modes of grinding

Bavarder sur Internet

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and ...

Bavarder sur Internet

Research on an Accurate Simulation Modeling and Charge

2024.6.12 A ball mill is a type of complex grinding device. Having knowledge of its charge-load behavior is key to determining the operating conditions that provide the optimum mill throughput. An elaborate description of the charge movement inside the ball mill is essential. This study focuses on a laboratory-scale ball mill and utilizes a discrete element simulation model

Bavarder sur Internet

Design and simulation of gear box for stone crushing ball mill

2022.1.1 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside. The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box. The gear box is a setup intended for making the power transmission from the electric motor to ...

Bavarder sur Internet

Articles liés

- dessins des composants des machines de construction en pdf

- Broyeur Indonésie Lame Indonésie Laitier

- spécifications de la route concasseur usine

- broyage fin dans un moulin à billes horizontal

- entreprise de concassage

- camion en vente en tunis

- broyeur de broyeurs machineries entreprises

- panduan membuat convoyeur de pierre concasseur

- cómo construir su propia trituradora de piedra

- Location de broyeur a beton dans l'Iowa

- pierres machines de concassage au Japon

- sable de construction fabriqués à partir de

- dolimite exportateur de concasseur mobile au Belgique

- les appareils de criblage a haut débit

- équipement pour traiter du sable de silice

- qui fournit des équipements pour les mines de charbon

- moulin de broyage matcha indonésie

- petit concasseur à percussion mobiles d'occasion à vendre

- broyeur pour pellets

- emplois mines de charbon amp 3bamp emplois miniers

- ciment broyeur Indonésie vendre

- minerales metalicos en guatemala

- machine requise pour le processus de ciment

- utilisation de la pierre de la carrière pour les routes

- broyeur à cone HP200

- broyeur de pierres Burnley

- zenith concasseur de roche remplacement d écran shaker

- Cedar Rapids concasseur Indonésie machoires 1036

- plan de revegetacion de botaderos

- entreprises qui font sable artificiel en afrique du sud