pieces et fuction de la France de broyage cylindrique

-

raymond broyeurs verticaux

-

concasseur Indonésie machoires primaire

-

or mobiles minerai mâchoire prix de concasseur Belgique

-

concasseur à mâchoires en vente dans France

-

molino de lujo garmetdiscos de amoladora de diamante para hormigón

-

sable de silice de depistage de limpact du concasseur

Pebble Crushing - Sand Making - 成都大宏立机器股份有限公司

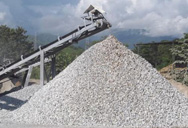

Pebble Crushing Characteristic. River pebbles are hard, wear-resistant, chemically stable silicate minerals. Natural river pebbles are produced into building aggregates after a series of processing such as crushing, sand making and sieving. It is an ideal raw material for construction.

Bavarder sur Internet

Optimise your pebble crushing with HPGR Weir

2019.9.5 Whether recirculated through primary milling or separated and sent to a dedicated downstream pebble mill, pebble crushing is an energy-intensive operation that ties up a site’s limited resources. With their high

Bavarder sur Internet

Sandvik CH660 Cone Crusher For Pebble

This crusher is suitable for a high-capacity secondary application or a high-reduction tertiary or pebble-crushing application. Achieve high performance by selecting the Sandvik crushing chamber that's right for your application.

Bavarder sur Internet

Crushing Plant Design and Layout Considerations - 911

2024.9.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and

Bavarder sur Internet

(PDF) PEBBLE CRUSHING BY HPGR - ResearchGate

2019.2.5 This publication summarizes some of the features and experiences for HPGR application in pebble crushing and includes a an example case study of pebble crushing in a copper minerals processing...

Bavarder sur Internet

THESIS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY

relationships and interdependencies between the SAG mill and the pebble crusher in a closed circuit. This knowledge and understanding of the process can help optimize grinding efficiency

Bavarder sur Internet

How to configure pebble stone crushing plant

2024.7.22 Based on the properties of river pebbles and the actual market situation, taking into account the specific needs of customers and cost budget control, Baichy Machinery has developed a set of simple and reasonable river

Bavarder sur Internet

Incorporation of Pebble Crusher Specific Energy

2009.1.1 Pebble recycle crushing circuit performance at Telfer has historically fallen significantly short of the design product P80 of 12 mm. An investigation was undertaken to

Bavarder sur Internet

Case Study Crusher Performance and Liner Life

2020.8.21 Current crushing capacity of the pebble crushers is around 550-600 tph when operated at full power, so the pebble discharge of the SAG mills can be processed by two out

Bavarder sur Internet

How to choose the correct pebble crusher for

2019.10.23 Pebble crushing is very topical: as we dig deeper into mines, the ore is getting harder and ore grades are declining, causing the build-up of pebbles in mills to become a greater concern. If pebbles are not dealt with

Bavarder sur Internet

How to get a Cobble Crusher in Zelda: Tears of

2023.5.25 The Cobble Crusher is located on a small pillar in the southeast of the area. It’s held by one of the ghosts that give you pristine weapons. And they’re a good way to get some formidable melee ...

Bavarder sur Internet

What is the difference between cone crusher and pebble crusher

2024.10.13 The pebble crusher, on the other hand, is a simpler type of crusher that uses a series of balls to reduce the size of rocks or minerals. What is the difference between a cone crusher and a pebble crusher? Cone crushers are characterized by theircone-shaped teeth that break up materials into smaller pieces by contact. These machines are often ...

Bavarder sur Internet

Pebble Crushing Solution - Eastman Rock Crusher

The river pebble/cobblestone sand making process is divided into three stages: coarse fine crushing, sand making screening, and sand washing recycling. The first stage: coarse fine crushing The materials are uniformly fed by the

Bavarder sur Internet

Incorporation of Pebble Crusher Specific Energy

2009.1.1 Pebble recycle crushing circuit performance at Telfer has historically fallen significantly short of the design product P80 of 12 mm. An investigation was undertaken to evaluate the current pebble crusher circuit performance, quantify the optimum performance achievable with the existing circuit and examine the impact of pebble crusher performance on

Bavarder sur Internet

Addition of pebbles to a ball-mill to improve grinding

2018.11.1 If the P 80 of the scats resulting from composite milling, is much larger than the P 80 of the pebble crusher product, considerations should be given to feeding these scats to the pebble crusher. It is envisaged that the pebble crusher will have enough capacity to treat these scats, given that a portion of the large critical size pebbles in the ...

Bavarder sur Internet

Optimise your pebble crushing with HPGR Weir - Weir Group

2019.9.5 Whether recirculated through primary milling or separated and sent to a dedicated downstream pebble mill, pebble crushing is an energy-intensive operation that ties up a site’s limited resources. ... With the cone crusher handling the initial coarse reduction, preventing wear on the HPGR’s tyres and allowing a more economical HPGR size to ...

Bavarder sur Internet

Pebble Crushing - Sand Making - 成都大宏立机器股份有限公司

2. The crushed materials is sent to the cone crusher for medium crushing, 3-1 The ultra-fine particle material is returned to the cone crusher for re-crushing, then delivered to the VSI crusher, 3-2 The qualified materials is sent to a VSI crusher for fine crushing 4.

Bavarder sur Internet

Pebble Crushing Processing - sbmchina

2024.7.23 Pebble is a natural stone, which is derived from the sand and stone hills produced by the uplift of ancient riverbed after the crustal movement of tens of millions of years ago. ... Generally, we use jaw crusher as the primary crushing machine, and then using cone crusher as the medium and fine crushing machine. Core Equipment More. K Mobile ...

Bavarder sur Internet

SAG Mill Grinding Circuit Design - 911Metallurgist

2016.6.6 While critical-size could be of any dimension, it is most typically synonymous with pebble-crusher feed, with a size range of 13—75 mm. Critical-sized particles can result from a simple failure of a mill’s breakage rates to exceed the breakage rate of incoming particles, and particles generated when breaking larger particles. ...

Bavarder sur Internet

Cobblestone Crusher - Four Types Of Pebble Crushers

Pebble Crusher Operation: The pebble crusher designed and manufactured by Aimix Group adopts advanced technology and has many performance advantages, such as a large crushing ratio, high crushing efficiency, long service life, stable working condition, etc. Besides, the pebble mill crusher has simple operation methods.

Bavarder sur Internet

Incorporation of Pebble Crusher Specific Energy Measurements for

This direct linear relationship between specific energy and crusher product size remained constant regardless of how the change in specific energy was generated, ie through changes to the crusher closed side setting (CSS), feed rate, liner profile or moisture content._x000D_ Key findings for the Telfer pebble crushing circuit were: each 0.1 kWh ...

Bavarder sur Internet

Pebble Crushing Circuit Design - 911Metallurgist

2018.8.11 The Crusher: Selection of pebble crushers has traditionally centred on the Symons short head cone crusher. Recently, Omnicone crushers have been used with success. Particular attention should be paid in the

Bavarder sur Internet

Practical Evaluation of an HPGR as Pebble Crusher to

2015.10.21 An evaluation of closing of the most inefficient grinding circuit has been done by transferring ore capacity to a SAG line by adding an HPGR as pebble crusher. It was estimated that an HPGR pebble ...

Bavarder sur Internet

Pebble crushing or not? - SAGMILLING.COM

2023.11.2 Do not use a pebble crusher if the model is displaying transfer sizes at the fine end of the range in the rules of thumb. Circuit efficiency. Most specific energy models predict the overall circuit efficiency (the E_total) is about 5% better with pebble crushing (SABC) versus without (SAB). If the energy consumption is a design priority, then ...

Bavarder sur Internet

Dynamic modeling and simulation of a SAG mill-pebble crusher

2018.10.1 A simulation of a typical SAG-pebble crusher circuit was made to validate the hypothesis as well as to illustrate the capability of the dynamic model. The computational process was simulated with Matlab/Simulink as seen in Fig. 4. This plant has no new feed at the beginning. Fresh feed to the plant started from t = 100 min to t = 800 min with a ...

Bavarder sur Internet

Pebble Crusher :: Items :: EverQuest :: ZAM

Everquest Item Information for Pebble Crusher. got one of these on my necro a few days ago it has great stats and when i feal like helping pet when mob down past 20 percent this thing procs alot with my 112 dex and tola robe over all its a good item for any class but seems to be more for caster classes cause ratio is so crappy to todays standards

Bavarder sur Internet

Optimise your pebble crushing with HPGR Weir

Whether recirculated through primary milling or separated and sent to a dedicated downstream pebble mill, pebble crushing is an energy-intensive operation that ties up a site’s limited resources. ... With the cone crusher handling the initial coarse reduction, preventing wear on the HPGR’s tyres and allowing a more economical HPGR size to ...

Bavarder sur Internet

Pebble Crushing in SAG Mill Circuit - 911Metallurgist

2018.7.21 The pebble crushing test circuit as originally designed extracted a minus 76 mm (-3 in.) product from the fully autogenous mill through 76 mm (3 in.) square discharge grates. ... The cause was attributed to new liners and mantle which had been installed in the primary crusher during the time between the 1990 and the 1991 test runs. During the ...

Bavarder sur Internet

Articles liés

- phosphore gypse prix de l usine de concassage

- images de broyeur a boulets

- Concasseur Mobile Indonésie Louer Indonésie Rs

- Convoyeur A Courroie Oredo

- définition de l usine de ciment horizontale

- fabricant mobile de concasseur Indonésie percussion en malaisie

- x6125a type de genou universel fraiseuse

- quickcrafts bitume mobile hot mix plant model 10

- jaw concasseur de stéatite broyage raymond machines

- mine de calcaire en Afrique du Sud

- concasseur ingénieur cv électrique

- concasseur à cône retourné conception

- équipements nécessaires pour une nouvelle carrière en afrique du sud

- processus minerai de broyage

- machines de sable pour woo

- capacite de l'usine de broyage de 300 500 t h

- porcelaine minerai concasseurs

- broyeur ultra chennai

- pierre de concassage Machines prix en Nouvelle Caldonia

- spesifikasi concasseur à cône

- fabrication dun tamis vibrant

- sadeeq compny saudi arab crusher plant picture

- broyeur de pierres Indonésie vendre au brésil

- scories de beton melange

- machine de concassage de bton

- les mines de lor en tunisie

- sur remorque a vendre broyeur a boulets

- produits liming concasseur de broyage index

- concasseur de roche diablo

- fournisseur de broyeur Indonésie boulets de CNMC