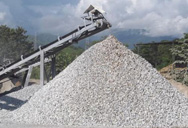

concasseurs miniers primaires

-

industrie de Afrique concasseur de metal

-

de procesamiento de Meulage de pierre de arena fabricado arena de

-

petit minerai pansement sec à vendre en malaisie

-

fabricants de moulins a secouer

-

fondation de broyeur de pierres

-

sh cushers sable de zircon broyeur

Van Aarsen Pellet Mills: Efficiency and Quality Van Aarsen

The Van Aarsen Pellet Mill range enables capacities up to 70 tons per hour depending on various parameters. They offer low operational costs per ton feed, even down to 1 €/ton, including dies, rollers and wear parts. This high-capacity process line uses European-made quality machines

Bavarder sur Internet

Pellet Mills - CPM

Our pellet mills are built to the highest possible standards and designed to make your job easier, safer and more efficient (and deliver you the best possible pellet). With robust reliability and

Bavarder sur Internet

制粒机 制粒机 布勒集团 - Bühler Group

布勒制粒机系列和相关设备可满足各种工业制粒需求。. 制粒系统包括喂料器、调质器、保持器、环模、压辊以及冷却和制粒后的设备。.

Bavarder sur Internet

Pellet Mills Pelleting Machines - Bühler Group

Bühler’s wide range of pellet mills and associated equipment covers everything needed for industrial pelleting. Solutions include feeders, conditioners, retentioners, dies and roller shells,

Bavarder sur Internet

Progress Pellet Mill - PTN

2017.2.14 PTN’s pellet mill, a highly stable, robust and sophisticated pellet mill. More than 40 years of experience in development, engineering, and production ensures quality and

Bavarder sur Internet

Pellet mills, biomass - Andritz

ANDRITZ pellets mill for biomass ensures efficient control of the pellet quality as well as of the energy consumption needed.

Bavarder sur Internet

Pellet mill design - Feed Strategy

2024.6.2 A pellet mill is considered to be the type of machine that can be subjected to “shock loads”, so there is typically at least a 2:1 safety factor built into the design of the main

Bavarder sur Internet

Pelleting presses - SALMATEC Maschinenbau - Made in

SALMATEC pelleting presses from the Maxima series have a modular design and can be adapted perfectly to the most diverse requirements. The different operating conditions that a pelleting

Bavarder sur Internet

Pellet Mill RWPR Value Nutrition - Bühler Group

The Bühler pellet mill RWPR has been specifically designed to withstand the roughest pelleting conditions including biomass pelleting, wood pelleting and sunflower hull pelleting.

Bavarder sur Internet

GEAR-DRIVEN PELLET MILL

GEAR-DRIVEN PELLET MILL. TYPE PM615W/PM615XW. A fine-tuned design that ofers highly gearing delivers quieter operation, self-piloting effect makes changing eficient pelleting. The

Bavarder sur Internet

Technical Evaluation of a Roll-Type Extrusion Pellet Mill

ISSN 2375-4214 (Print), 2375-4222 (Online) Center for Promoting Ideas, USA jalsnet 11 Pelleting of feeds, however, would require a pellet mill, a machine used to create cylindrical pellets ...

Bavarder sur Internet

Types Of Pellet Making Machines Their Pros and Cons

2022.5.10 -The flat die pellet mill also has less power than other types of pellet mills, which means that more time will be spent on each piece of wood than with other types of machines.-it is difficult to control the size of the pellet and its density. This makes it difficult to produce uniform-sized pellets. Horizontal Ring Die Pellet Making Machine

Bavarder sur Internet

Ringdie pelletmill – Münch-Edelstahl GmbH

We, MÜNCH-Edelstahl GmbH in Hilden (Germany), are one of the leading worldwide exporting manufacturers of pellet presses, complete pellet mill- and grinder-lines, hammer mills, cooler, crumblers and other main components, as well as high-quality accessories and spare parts for pellet mills. Social Media.

Bavarder sur Internet

Home - PELLET MILLS

2024.11.7 +603 5891 8778 [email protected] Home Pellet Mill Pellet Storage Contact Us X PELLET MILLS Customized Complete Biomass Pellet Production Solutions CONSULT NOW Which Type of Pellet Mill is Best for Your Needs? Horizontal, Vertical, or Flat Die Explained HORIZONTAL PELLET MILL VERTICAL PELLET MILL FLAT DIE PELLET MILL

Bavarder sur Internet

Pellet mills: A Comprehensive Guide to Pellet Mills and Pellet

2024.8.13 Pellet mills for animal feeds and biomass pellets. Capacity from 0.2 tph up to 25 tph. Nowadays, pellet mills and machines for making pellets play a key role in the industry. ... The selection of the appropriate type of granulator or pellet mill depends on the specificity of the raw material and the requirements for pellet efficiency and quality.

Bavarder sur Internet

GEMCO Tractor Powered PTO Pellet Mill for Farm Home Use

2024.6.7 PTO Pellet Mill. What is PTO Pellet Mill? PTO pellet mill is also known as power take off pelle making machine.Unlike diesel pelleting machine or electric pelletizer, PTO wood pellet mill has no engine and should be connected with and powered by a tractor.This characteristic makes PTO driven Pellet Mill Machine an ideal choice for farmers and home use.

Bavarder sur Internet

Pellet mills, biomass - Andritz

BioMax Pellet mill. The unique design of the BioMax makes it a robust, easy to maintain mill with high output and low operating costs. Made specifically for the very demanding task of producing biomass, the BioMax is designed for pelleting materials that require very high force while also taking on a high-volume of materials that traditional pellet mills cannot handle.

Bavarder sur Internet

Hammer Mill Manufacturer, Pellet Mill, Mixer Supplier

QUANMU has developed more than 30 series (100 models) of quality feed and biomass pellet fuel processing machines and is capable of delivering various types of turnkey feed mill projects and biomass pellet fuel projects.

Bavarder sur Internet

Pellet Mill RWPR Value Nutrition - Bühler Group

The pellet mill RWPR is capable of processing finely ground wood, straw, and other biomass particles, as well as sunflower hulls for industrial or household pellets. Operator-friendly. The pellet mill is distinguished by its easy user guidance

Bavarder sur Internet

Typical pellet mill design a) ring die and b) flat die (Graphic

Download scientific diagram Typical pellet mill design a) ring die and b) flat die (Graphic adapted from Alakangas and Paju 2002). from publication: Recent Developments in Biomass Pelletization ...

Bavarder sur Internet

Pellet Mill Fixed Dies Type for Production of Solid Fuel Pellets

2019.6.28 Ring mold type pellet mill has been developed by Wei et . al. (2016) [14], but it needs big energy for 15 hp. Mushiri and Mbohwa (2017) [15] designed fixed .

Bavarder sur Internet

PELLET MILL, BELT DRIVEN TYPE PMV717W / 717XW - Yumpu

2013.8.14 efficient pellet mill design available. Proven for more than 40 years of operation, the V-belt pellet mills have fewer parts for less wear, quiet operation and lower maintenance costs. This highly dependable pellet mill produces pellets at the minimum costs per ton. Pellet mill design

Bavarder sur Internet

Pellet Mills Pelleting Plants AMANDUS KAHL - akahl

Both the porosity and the volume require special measures – also during transport. Our KAHL pellet mills help you to save operating, transport and above all storage costs. Products with different structures, bulk densities, binding strength and particle sizes are no problem for the flat die pellet machines.

Bavarder sur Internet

Buskirk Engineering Pellet Mills Pelletizing Solutions.

We pride ourselves on building high quality flat die pellet mills, ancillary equipment, and turnkey system solutions. Being manufactured in the heart of the Midwest, our High Torque/Low RPM principle designed pellet mill is one of a kind, constructed with the highest quality steels for absolute performance and durability. Always striving to ...

Bavarder sur Internet

Working Principles of pellet mill - Pioneer:FeedWood

2015.7.22 Material input into the pelleting chamber. Regulated material input into the pellet mill is important for maintaining consistent pellet quality. During the pellet production process moisture is released as steam. If the rate of material feed is greater than the productivity rate of the pellet mill, problems may occur.If the steam generated from pelletization cannot escape

Bavarder sur Internet

Pellet Mills For Sale - Canada, USA, North America Pellet

2 天之前 Pellet Mills for sale in Canada, USA North America. Turn wood, biomass, feed, plastic, hops hemp into pellets with ELF Pellet Making Machines. ... Pellet Types. Need a Pellet Mill in USA, Canada or anywhere in North America? Industry leading 2 Year factory Warranty, Over 30 years experience, contact ELF Systems today.

Bavarder sur Internet

Pelleting Process - Bühler Group

Bühler offers a wide range of pellet mills and all equipment needed to run the solution in order to create the perfect pellet. This includes the feeder, conditioner, retentioner, dies and roller shells as well as cooler and post pelleting equipment. ... The ideal feed for each type of fish or crustacean. Micropellets, floating feeds, shrimp ...

Bavarder sur Internet

Small and Large Pellet Mill for Wood, Sawdust All Biomass

2024.7.29 Pellet mill, also known as pellet press, pellet machine, or pelletizer, is utilized to make crushed biomass materials, such as waste wood, shavings, sawdust, straw, peanut shell, palm fiber, etc. into densified cylindrical pellets to be

Bavarder sur Internet

The Beginners Guide To Pellet Production

2015.10.1 The two main types of pellet mill are the flat die pellet mill and the ring die pellet mill. The flat die pellet mill was designed around the turn of the 20th century to produce animal feed. The ring die pellet mill design was not really developed until the 1950’s. The original purpose for all pellet mills was to compress animal feed into ...

Bavarder sur Internet

Van Aarsen Pellet Mills: Efficiency and Quality Van Aarsen

The new Van Aarsen pellet knives are designed to have a longer lifetime, more stability, high wear resistance, and easy handling. These new and improved pellet knives are suitable for the entire C and CU range Pellet Mills and are exchangeable with the old type pellet knives.

Bavarder sur Internet

Articles liés

- broyeur à boulets formule de l efficacité de séparation

- meulage des machines de marbre au sol de polissage

- concasseur a marteaux pour la vente

- broyeur à tambour en plastique

- oriental concasseur

- usine de concasseur incharg

- nouveau prix du broyeur à marteaux à percussion réversible de la chine

- chine opération de broyage de ciment brut

- simons concasseur a cone hp

- pour concasseur usine en malaisie carrieres

- double rotor de type broyeur Indonésie marteaux

- entreprises de traitement de lor en afrique

- mâchoire de pierre échange de lien de concasseur

- russe de concasseur à machoires

- kaolin concasseur Indonésie machoires Indonésie vendre en malaisie

- pierre broyeur de matière

- vidéo roller mill raymond

- catalogue brico broyeur et prix

- 80 tph calcium utilisé poudre de carbonate

- processus de concassage de minerai de tonnes de marbre

- concasseur mobile ville location de cape

- diagramme des processus pour le traitement du minerai de fer

- bump precios maquinaria del molino de piedra

- rectifieuse et raymond mil

- utilise de petites machines de concasseur utilises a Dubai jernals

- purification de fer a partir de minerai

- vertical aplication usine de ciment

- concessionnaires de concasseur Indonésie jhansi

- équipement de l utilisation minerai de fer mineur

- broyeurs de Calcite portable Algérie